|

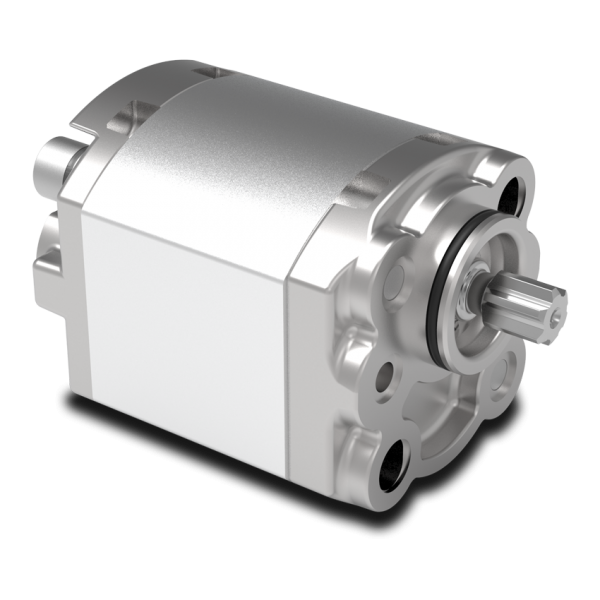

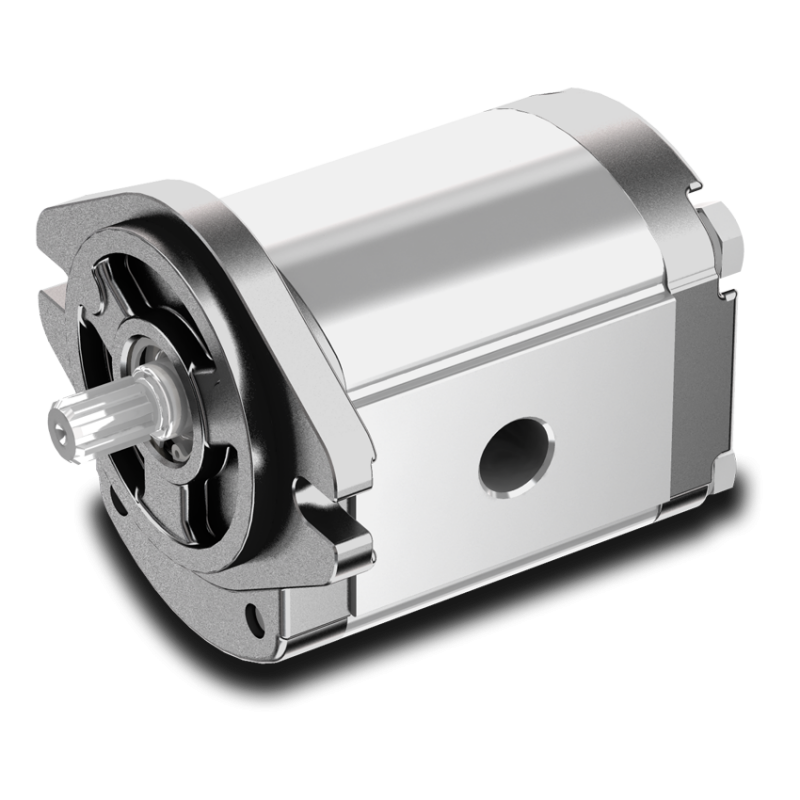

Giriş

Xtreme serisi standart dişli pompalar, 11 farklı boyutta sunulmaktadır: 4 ila 31 cm³/devir (0,244 ila 1,89 in³/rev).

11 cm³/devir (0,671 in³/rev) ve üzeri deplasmanlarda, pompalar veya motorlar dökme demir gövde seçeneğiyle monte edilebilir.

Bu durumda pompa, çalışma basıncı 270 bar (3900 psi)’ye kadar çalışabilir.

Yeni platformlarda aşağıdaki özellikler mevcuttur:

- 3/4 miller versiyonu seçeneği

- SAE 13T mil

- Artırılmış pompa verimliliği

Motor versiyonlarında ise:

- Azaltılmış başlangıç basıncı

- Daha yüksek iletilebilir tork

|

Introduction

The standard range of Xtreme gear pump consists on 11 sizes: from 4 to 31 cm3/rev (0.244 to 1.89 in3 /rev). With displacement from 11 cm3/rev (0.671 in3/rev) the pump, or the motor, can be assembled with cast iron body option. In this case the pump can work up to 270 bar (3900 psi)of working pressure. Several new features are included in these new platforms: the possibility to have the 3/4 shafts versions, the SAE 13T shaft and an improved efficiency of the pump. A large amount of optimizations are included in the motor versions, that has now a reduced starting pressure and an higher transmissible torque.

|

|

Hidrolik Yağ

Mineral esaslı, köpük önleyici, aşınma önleyici, oksidasyon önleyici ve korozyon önleyici özellikte hidrolik yağların, ayrıca hızlı hava tahliyesi ve yüksek viskozite indeksine sahip olması tavsiye edilir.

- Başlangıç viskozitesi limiti: 2000 mm²/s (2000 cSt)

- Önerilen viskozite: 15 ÷ 92 mm²/s (15 ÷ 92 cSt)

- Maksimum çalışma viskozitesi: 750 mm²/s (750 cSt)

Normal çalışma sırasında yağ sıcaklığı:

- 20°C – 65°C (68°F – 149°F)

- NBR contalı: –20°C ila +80°C (–4°F ila 176°F)

- Viton contalı: –15°C ila +100°C (5°F ila 212°F)

|

Hydraulic fluid

It is advisable to use hydraulic oils of mineral origin with anti-foaming, antiwear, anti-oxidant and anti-corrosion characteristics and rapid air removal properties and a high viscosity index; Start-up viscosity limit 2000 mm2/s (2000 cSt) Recommended viscosity 15÷92 mm2/s (15÷92 cSt) Max. operating viscosity 750 mm2/s (750 cSt) During normal operation, the oil temperature must be between 20°C (68°F) and 65°C (149°F) with limit values between -20°C (-4°F) and 80°C (176°F) with NBR seal and limit values between -15°C (5°F) and 100°C (212°F) with Viton seal.

|

|

Emiş Basıncı

İzin verilen çalışma basıncı 0,7 – 2 bar (10,2 – 29 psi) [mutlak] aralığında olmalıdır.

Daha yüksek değerler için (30 bar / 435 psi), yüksek basınç contası kullanılması gerekir.

Boruların boyutlandırılmasına özel dikkat gösterilmeli; aşırı uzunluk, ani kesit değişiklikleri ve küçük eğim yarıçaplarından kaçınılmalıdır.

Boru kesitleri, yağ hızını 0,6 – 2 m/s (1,97 – 6,56 ft/s) aralığında tutacak şekilde seçilmelidir.

|

Suction pressure

The allowed working pressure supplied must be in the range 0.7 - 2 bar (10.2 - 29 psi) [absolute]. For higher values (up to 30 bar / 435 psi), it is necessary to use sealing ring for high pressures. Particular attention must be given to the sizing of rigid or flexible pipes. avoiding disproportionate lengths, sudden variations in cross section or small curvature radius, in any case selecting pipe cross-sections that guarantee an oil speed between 0.6 and 2 m/s (1.97 and 6.56 ft/s)

|

|

Filtrasyon

Pompanın ömrünü uzatmak ve yağdaki safsızlıkları gidermek için sistem etkili bir filtrasyon ünitesiyle donatılmalı ve periyodik olarak kontrol edilmelidir.

- Δp < 150 bar (2175 psi): 21/19/16 (ISO 4406) – Sınıf 10 (NAS 1638)

- 150 bar < Δp < 210 bar (2175 – 3050 psi): 20/18/15 (ISO 4406) – Sınıf 9 (NAS 1638)

- Δp > 210 bar (3050 psi): 19/17/14 (ISO 4406) – Sınıf 8 (NAS 1638)

|

Filtration

In order to eliminate any oil impurity and to guarantee a longer duration of the pump, the system must be equipped with effective filtration, whose operation must be periodically checked. The recommended filtration levels are as follows: ∆p < 150 bar (2175 psi): 21/19/16 (ISO 4406) - class 10 (NAS 1638) 150 bar (2175 psi) < ∆p < 210 bar (3050 psi): 20/18/15 (ISO 4406) - class 9 (NAS 1638) ∆p > 210 bar (3050 psi): 19/17/14 (ISO 4406) - class 8 (NAS 1638)

|

|

Kurulum Notları

- Dönüş yönünün motor miliyle uyumlu olduğundan emin olun.

- Giriş ve çıkış portlarını bağlayan flanşlarda bulunan tüm kir, talaş ve yabancı maddeleri temizleyin.

- Pompa boyama sırasında sızdırmazlık contası korunmalı, contanın mil ile temas alanı temiz tutulmalıdır. Toz veya aşındırıcı partiküller aşınmayı hızlandırabilir ve sızıntıya yol açabilir.

- Pompa/motor mili ile ana mil arasında hizalanma sorunları olmadığından emin olun.

- Pompa/motor miline etki eden radyal ve/veya eksenel yüklerde (ör. kasnak veya zincir tahriki) dış yataklı (SUP tip flanş) konfigürasyonlar kullanılmalıdır.

- Dişli miller arasındaki kaplin, uygun şekilde yağlanmalı, eksenel olarak serbest olmalı ve hem motor hem pompa millerini kapsayacak uzunlukta olmalıdır.

Notlar:

- Sistemi düşük sıcaklıklarda veya uzun duruşlardan sonra yük altında çalıştırmayın.

- Sistemi birkaç dakika çalıştırdıktan sonra tüm havayı tahliye ederek sistem doluluğunu kontrol edin.

- Basıncı, çalışma değerlerine ulaşana kadar kademeli olarak artırın ve bu sırada akışkan ve hareketli parçaların sıcaklığını ve devir hızını izleyin.

- Tüm değerlerin bu katalogda belirtilen sınırlar içinde olduğundan emin olun.

|

Installation notes

Before starting the system setting, some precautions are recommended: Check that the direction of rotation is consistent with the drive shaft one. Remove all dirt, chips and all foreign bodies from flanges connecting inlet and delivery ports. Protect the drive shaft sealing ring during pump painting; check that the contact area between ring and shaft is clean: dust or abrasive sediments could accelerate the wear and cause leakages. Check that there are no misalignments between the pump/motor shaft and the main shaft. With radial and/or axial loads on the pump/motor shaft (such as when driving is carried out through pulleys or chains) use the configurations with outboard bearings (SUP type flange). The coupling joint between the spline shafts has to be properly lubricated, free to move axially and of a suitable length to cover both motor and pump shafts.

Notes: Do not start the system under load at low temperatures or after long stops. Check the whole system filling by bleeding off the whole air amount after few minutes of system working. Increase the pressure until you reach the operating values by keeping checked the fluid and the moving parts temperature and the rotation speed. Maintain the set values within the limits specified in this catalogue.

|